By contrast, Kathryn Brenne's method worked perfectly, the first time (a practice zipper) and the second and third times too (the real thing)! Here's how:

First, prepare your seam. Interface the pocket opening if it isn't already. In my jacket, the centre front panel is fully interfaced but not the side panel. I cut a strip of fusible and applied it as shown to the left. Mark the pocket opening. Then sew the seam above and below it. Press the seam open, including the seam allowances beside the pocket opening.

It turns out that things go a lot better when you have the right tricks up your sleeve. The trick, in this case, is Wonder Tape. Stick this stuff on the zipper tape, both sides, as shown to the right.

Next, peel off the Wonder Tape paper backing on one side. Position the zipper so the top stop is a little bit above the end of the stitching at the top of the pocket opening (above). The bottom stop should be a bigger bit below the end of the stitching at the bottom of the opening (right). Stick the zipper down on the seam allowance so that the coil is just along the pressed-open seam allowance on that side.

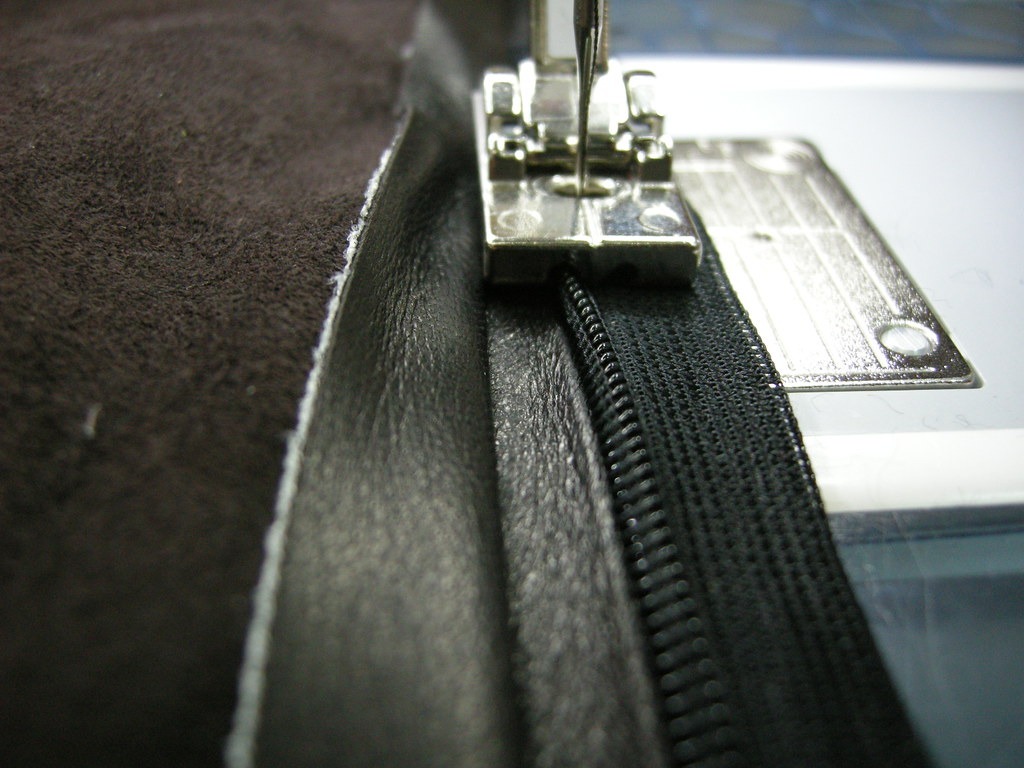

Sew that side of the zipper down using your choice of special foot. At left is the Bernina invisible zipper foot. The first side is easy, I tell you. The second is much harder because you have to somehow get the zipper coil in the opposite groove while the first side of the zipper is snugged right up against it. When I complained about this, Kathryn said "It'll be fine. That part of the stitching is in the seam allowance and you will never see it." She said exactly the same thing when I complained that it was hard to sew right to the bottom of the zipper on the second side.

And just look at the mess I made of it! Oh no!

Once both sides are sewn, you have to fish the zipper pull out of the little well you've sewn it into below the pocket opening so that it's accessible in the pocket opening.

Look! Kathryn was right! No sign of the ugly mess behind.

It'll be fine...