Hello. You may remember me. I'm The Sewing Lawyer.

Again, I have been busy, in what passes for real life around here. I have this full time job which takes me away from sewing, knitting and blogging. Nevertheless I have slowly been making progress on a few fronts, though not blogging, evidently.

|

| Easter sunrise socks |

I made some more socks. I know, yaaawwwn. But for posterity, they are precisely the same as the last ones; the

blue pair (finished in Halifax). Except obviously they are a very different colour.

On Ravelry, there is a free pattern for a stitch pattern to disguise ugly sock yarn (the

Ugly Duckling Socks, if you are on Ravelry). I kind of wish I had started these socks with a sober solid colour for contrast. They are (ahem) very bright. My sole innovation was instead to try to start sock #2 at the same point in the colour progression as sock #1. This was very unscientific and it only almost worked. However I consider it close enough.

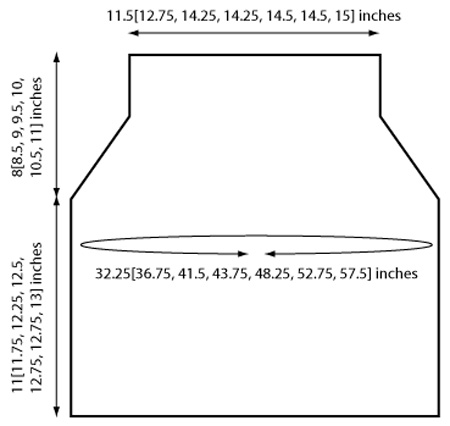

I'm also knitting another little summer top. It's a free pattern from

Knitty called "Etherial". I'll save my review for the next post. For now, This will have to suffice: Lace weight. Oy!

I have been sewing too (Yay!). The suit is somewhat closer to being wearable, and The Sewing Lawyer has done it again folks. The wool suit will be unwearable once complete, due to a very predictable break out of warmer weather, expected to last for months. I console myself with the thought of the delightful surprise I will have, come September or so, on rediscovering its pristine, probably unworn newness in my closet.

Sorry for having to feed you with more progress shots. But the jacket has really taken shape. It does actually have sleeves, and a (partially completed) lining, but it seems I'm going to make you wait until the thing is completely finished with arms in it.

You can see I inserted piping at CF, around the lapels and collar. I'm really pleased at how easy this turned out to be, and how good it looks. I thought of using two pieces which would end/overlap at the notch, but then thought I'd first try a single pass, and to my amazement it worked really well. Much trimming of the bulky fabric, along with strategic clipping and much steam and pressure, was required to get it all to lay flat enough.

BTW, if you haven't already, get a really good iron (I love my

Consew gravity feed iron and Reliable board).

Finishing the inside of the bound buttonholes required some mental preparation. Given how much my fabric ravels (and that I had not used any fusible on the jacket facing), I decided to use silk organza squares to make no-bulk windows in the facing. I located the corners of the buttonholes by jabbing pins straight through all layers, then double- and triple-checked these by measuring, before using a small stitch length to sew the organza via buttonhole shaped rectangles, clipping and turning. I have now sewn the facing to the buttonholes from the back, by hand. And all I can say is that it's a good thing my fabric is all black, and that hand stitches virtually disappear in the fabric of both the jacket and the buttonholes themselves, because it is not all that wonderful a hand-sewing job.

However, onward!

Next I am going to complete the jacket lining, and the jacket will be all done but for the sewing on the buttons.

The skirt is also almost in the home stretch. I have to assemble the lining, and do the hem.

Maybe I can finish them both today, while there is still some chill in the air?

The sleeves are slightly shorter than the pattern calls for - they hit at my elbow. The length of the body is slightly longer than the pattern calls for - I wanted it to end at about the same spot as the matching top.

The sleeves are slightly shorter than the pattern calls for - they hit at my elbow. The length of the body is slightly longer than the pattern calls for - I wanted it to end at about the same spot as the matching top.