Knitting. Sometimes you start slow and simple (bottom rib band of a sweater or the top rib band of a sock) and sometimes you have to plunge right into some sort of complicated manipulation or technique. Inevitably there will be chunks of relatively mindless knitting (back and forth, around and around) on an established number of stitches, and transition points where you have to engage your brain. However, overall knitting gives you lots of time to think.

If you are making anything to fit the human body, the characteristics of knitting are truly wonderful. Its geometry and the fluidity of knitting combine to allow you to make the stitches flow and grow or decrease as the case may be, turn corners, attach new garment segments sideways, make holes and close them up again as needed, and do virtually anything to make the needed shape. Knitting designers love all this stuff. But do they care about fit?

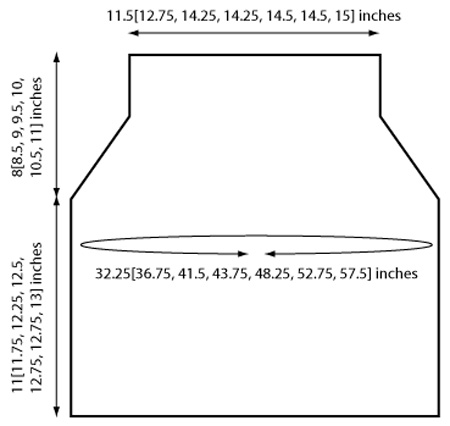

|

| Chic Knits - Vonica Pattern |

Right now, I'm working on a cardigan. It combines a relatively simple lace pattern (7 stitch repeat over 16 rows) with some mindless stockinette sections. The pattern is by an accomplished designer, Bonnie Marie Burns (

Chic Knits). It's called

Vonica. It was first published on Ravelry in April, 2011. As of today, it has been favorited by 2,727 people, making it one of her most popular patterns, although there are "only" 184 projects posted on the site as of today.

People really like this sweater. As does The Sewing Lawyer, I hasten to add. (I actually can't wait to finish this - I

SO need a black cardigan...) It's just that, from a fit perspective, it's kind of strange. More on that below, but first read about how this sweater is built.

|

| Progress so far |

Construction-wise, the pattern grows out of the centre back collar. You do a provisional cast on, knit a narrow strap to form the back collar, cast on to make the piece a lot wider for the shoulder on one side, and work the front down to the bottom of the armscye. (This seems to flummox lots of knitters, judging from comments I've seen on Ravelry, but produces a shape that is completely logical to anyone who has ever sewn a garment with a shawl collar.) Next, it's back to the CB collar where you work in the opposite direction from your provisional cast on to make a mirror-image piece for the other front. Then you pick up stitches along the cast on front shoulder edges and the lower edge of the collar, and work the back down to the bottom of the armscye before casting on additional stitches at the armscye (for under the arm), joining front to back, and knitting seamlessly down to the ribbed hem. Then you pick up stitches all around the armscye and knit the sleeves, in the round, down to their ribbed hems. It's truly ingenious, as per comments above about knitting's fluidity and ability to change direction.

I've just finished the body, and have started on the left sleeve. To the right, you can see what it looks like so far. Once it's blocked, the fabric should actually cover me ... although this cardigan is designed to be unfastened and looks pretty good even if the front edges don't touch or overlap.

Here's the weirdness, at least to this sewing person. Everybody knows (don't they?) that the back, above the armscye, needs to be

wider and

longer than the front to fit the body. If it isn't, the garment shoulders will slip to the back, as the relatively-too-short back borrows fabric from the relatively-too-long front. Moreover, the wider front shoulders will facilitate the garment's tendency to slip to the back.

Bonnie Marie Burns did not follow these "rules". This pattern has many

fewer stitches at the shoulder line in the back (22 in my size) than the front (29). In the intended gauge of 20 stitches to 4" (10cm) that's a dimensional difference of about 1.4" (3.5cm) Personally, I think the back fits my relatively narrow shoulders correctly. At left, you can see that the edge of the back armscye lies pretty much straight down from the shoulder point. At right, a view from above showing that, as I would have expected, the actual shoulder line (red) is slipping to the back. The blue line is the actual top of the shoulder. Believe me, the edge of the sleeve at front is falling off the shoulder. The fit of this cardigan is going to be quite different in the front than it is in the back. Neither is, in the abstract, wrong or bad, but shouldn't they match?

I get that knitting is different from sewing, and its qualities allow different fitting norms to apply. But do they have to be so different? Is there something technical that requires this garment to be constructed this way?Or should The Sewing Lawyer stop fussing and enjoy the process?

Does this look like a lawyer's suit to you?

Does this look like a lawyer's suit to you? I also got lazy in relation to the back walking vent. Instead of making a concealed vent, properly lined (as per my tutorial here - the most-visited page on this blog, by far), I just folded the vent facings back at the seam line and tacked it invisibly by hand to the facing, leaving a little extra length for ease above the top of the vent. I mitered the hem and facings for a clean finish but it's practically invisible in this fabric.

I also got lazy in relation to the back walking vent. Instead of making a concealed vent, properly lined (as per my tutorial here - the most-visited page on this blog, by far), I just folded the vent facings back at the seam line and tacked it invisibly by hand to the facing, leaving a little extra length for ease above the top of the vent. I mitered the hem and facings for a clean finish but it's practically invisible in this fabric.  And that is that.

And that is that.